This website uses cookies for a better browsing experience.

If you agree to the use of cookies, please click the "Agree" button.

Please refer to the Privacy Policy regarding the use of cookies on this site.

These sliding bearings use an Oiles bearing as a sliding material.

BP・A A high-strength brass BP bearing Fixed & movable

The Oiles BP・A is a sliding bearing that uses an oil-less BP, which has excellent corrosion resistance, load-carrying capacity, wear resistance, and a low coefficient of friction, as the sliding material.

Features

- It maintains consistent performance over a long period of time for features required of bearings, such as support of a load and absorption of girder expansion/contraction and rotation.

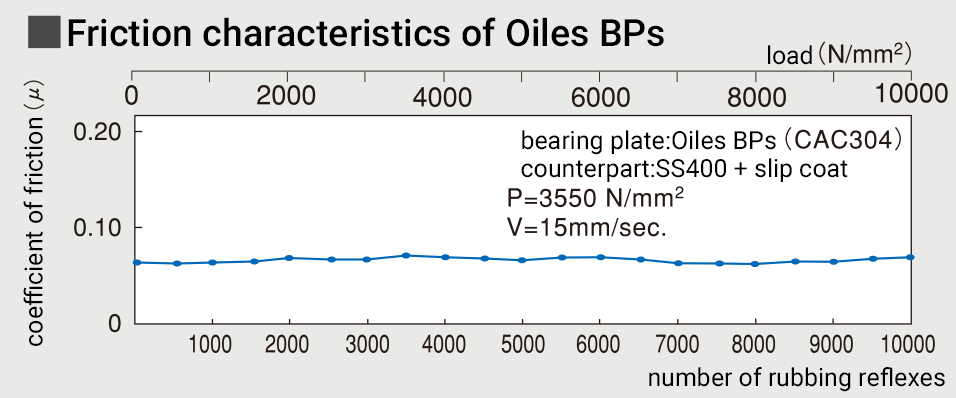

- An Oiles BP is used as the sliding material, providing an extremely low coefficient of friction and excellent load resistance.

- Oiles BPs have excellent corrosion resistance, weather resistance, and durability, and they perform well under harsh conditions.

BP・B A sealed rubber BP bearing Fixed & movable

The Oiles BP・B is a sliding bearing that uses an Oiles Glitron plate, which has excellent corrosion resistance, load-carrying capacity, abrasion resistance, and a low coefficient of friction, as the sliding material. Chloroprene rubber is sealed inside the lower shoe by an intermediate plate.

Features

- It maintains consistent performance over a long period of time for features required of bearings, such as support of a load and absorption of girder expansion/contraction and rotation.

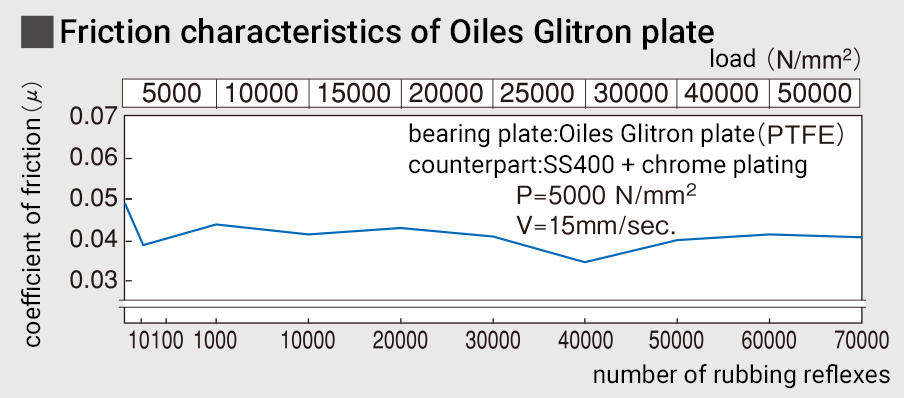

- The Oiles Glitron Plate has an extremely low coefficient of friction and excellent friction and load-carrying capacity.

- Chloroprene rubber has excellent resistance to weather, ozone, oil, and heat, and it performs well under harsh conditions.

Basic characteristics

Oiles BPs

Oiles BPs are based on grade four high-strength brass (JIS H 5120) castings made with advanced casting technology and embedded with a special solid lubricant. The lubricant maintains consistent characteristics by evenly forming a lubricating film with respect to sliding in any direction.

| BP (high-strength brass casting) characteristics (Test method: JIS H 5120) | ||

|---|---|---|

| Tensile strength | Elongation | Brinell hardness |

| 755 N/mm2 or more | 12% or more | 200 or more |

Oiles Glitron plate (Sliding Plate)

Oiles Glitron plates are based on polytetrafluoroethylene (PTFE) with special fillers and have an extremely low coefficient of friction, excellent corrosion resistance, load-carrying capacity, and abrasion resistance.

| Characteristics of Glitron plates (Test method: JIS K 6888) | |

|---|---|

| Specific gravity (25/25°C) | 2.10-2.40 |

| Hardness (Shore D) |

50 or more |

| Tensile strength | 1,400 N/mm2 or more |

| Elongation | 90% or more |

| Chemical resistance | It is virtually impervious to acids and alkalis. |

Chloroprene rubber (rubber plate)

Chloroprene rubber has excellent durability, weather resistance, ozone resistance, heat resistance, and oil resistance.

| Characteristics of chloroprene rubber (Test method: JIS K 6301) | |

|---|---|

| Static shear modulus | 80±10 N/mm2 |

| Elongation | 400% or more |

| Change in hardness (JISA) | 0- +15 (100°C x 70 h) |

| Rate of change in elongation | -50% or more (100°C x 70 h) |

| Compression set | 35% or less (100°C x 22 h) |