This website uses cookies for a better browsing experience.

If you agree to the use of cookies, please click the "Agree" button.

Please refer to the Privacy Policy regarding the use of cookies on this site.

Cable-stayed bridge cables are inherently prone to swaying due to tension, and winds above a certain wind speed or winds during rainfall can cause large vibrations.

The Oiles Cable Vibration Damper is a device that suppresses those cable vibrations via the shear resistance of an Oiles viscous body.

Features

- A single damper can handle cable vibration in two directions (vertical and horizontal) and can follow the movement of the damper attachment point due to fluctuations in cable tension or other causes.

- Excellent vibration control starting with minute vibrations with an amplitude of 0.5 mm or less.

- The structure is simple and compact, with no mechanical contact points or rattling due to mounting. It is highly durable and easy to maintain.

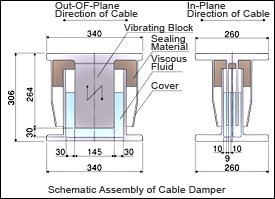

Structure

- The Oiles Cable Vibration Damper consists of its cover, which is attached to the cable, and its body, which is mounted on the girder.

- The body is divided into two chambers that are filled with viscous material. The cover’s oscillator (two thin plates inside the attached cover) is inserted from above, creating four shear surfaces on the viscous body. (The dimensions below are for reference only). )

- Inspections

If the damper is subjected to strong winds such as typhoons or vibrations caused by earthquakes with an intensity greater than 5, conduct a temporary inspection to confirm that there is no damage to the mount or main body and that there is no leakage of viscous material.

Oiles viscous body

- The Oiles viscous body is a high-viscosity polymer with excellent flame resistance, weather resistance, and thermal stability.

- The Oiles viscous body degrades little over time and can maintain vibration control a long period of time.

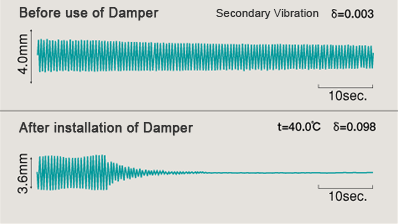

Damping

- Vibration measurements on an actual bridge revealed excellent damping of vibrations with a single amplitude as small as 1.0 to 2.0 mm (see figure for a comparison of free vibration waveforms).

- Moreover, the effectiveness of damping was confirmed with micro-amplitudes in the range of 0.5 mm or less.

Figure: Damping (comparison of free vibration waveforms)