This website uses cookies for a better browsing experience.

If you agree to the use of cookies, please click the "Agree" button.

Please refer to the Privacy Policy regarding the use of cookies on this site.

Oiles Bearings for Reduced Environmental Impact

Oiles bearings help to reduce environmental impact across broad industrial areas.

Oiles bearings constructed from our unique technology are plain bearings that can be used with either no lubrication at all or with reduced frequencies and amounts of lubrication.

They have higher durability than general plain bearings, which in and of itself reduces environmental impact. Still, their ability to operate with either no lubrication at all or with reduced frequencies and amounts of lubrication also reduces environmental impact.

For concrete numeric values indicating how much this can contribute to reducing environmental impact, see the three examples below.

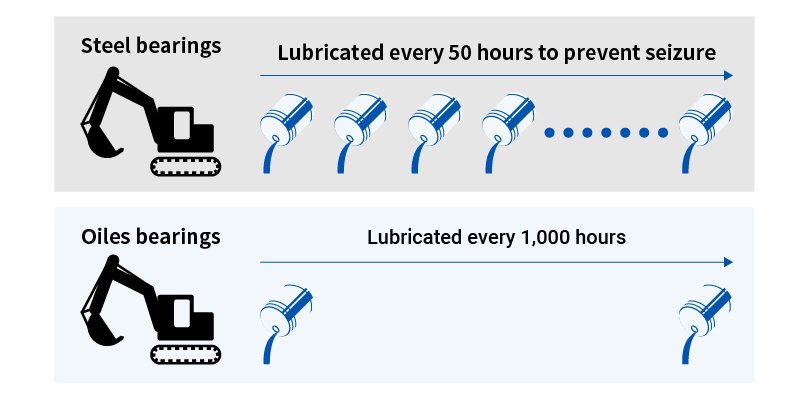

Hydraulic Shovels

The bearings in the links of hydraulic shovels, which perform excavation and leveling at construction sites, are used in harsh environments where they are subject to heavy weights and the infiltration of sand and soil. Due to these harsh conditions, lubrication is normally performed every 50 hours to prevent seizure damage, but with Oiles bearings, only 1/20 of this lubrication is required, or every 1,000 hours. Not only does this extend the product life, but expanding the lubrication interval reduces the amount of oil used.

Railway Switches

Railway turnouts are used to switch trains onto other rails to change their route, and railway switches are used in harsh environments where the base plates are exposed to the elements and subject to impacts caused by the sliding of rails, which can also cause the infiltration of foreign material. If a rail cannot move, the train will not move in the intended direction, so lubrication is required once every three days. By switching to Oiles bearings, inspections are only required once or twice a year, which is 30 to 120 times less frequent than before. As mentioned above, expanding the lubrication interval reduces the amount of oil used and saves labor for maintenance work.

Hydroelectric Power Generators

With a hydroelectric power generator, where power is generated by dropping water from a high location such as a dam, water is used as the medium to operate machinery, and parts such as the fins used to adjust the amount of water may rust due to exposure to water. Other problems may also occur, such as long-term wear causing oil to leak out from gaps into waterways such as rivers. Oiles bearings are highly durable and water-resistant, and because they require no lubrication, they help prevent pollution because no oil will leak into rivers. Switching to lubrication-free operation saves on oil and can help prevent water pollution.

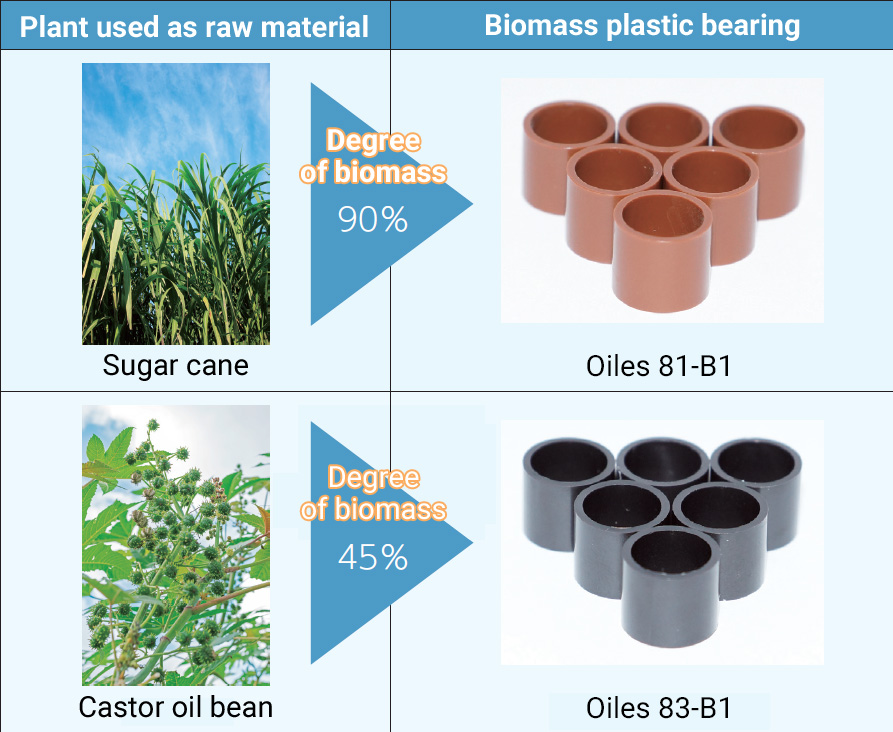

Biomass Plastic Bearings

In recent years, we have developed environmentally-friendly bearings manufactured using renewable organic materials derived from plant matter. Plastic (or resin) is conventionally made from petroleum, but our biomass* plastic bearings have a high biomass degree and excellent performance since fillers are added to improve the sliding performance of biomass plastics refined from sugar cane and castor oil bean. As a result, CO2 emissions can be reduced compared to conventional products derived from petroleum. Because biomass plastics are derived from plant matter instead of exhaustible resources like petroleum, they can be sustainably made from renewable organic resources, and demand for such products is expected to increase in the future as an effective means for tackling global warming.

*Resources derived from renewable biomass (excluding fossil fuel resources)

81-B1 and 83-B1

Renewable Energy

In the field of renewable energy, we are developing bearings with remarkable frictional efficiency that will contribute to stabilizing and improving the performance of wind power generators. Our bearings are also used in demonstration tests for wave power generation, a next-generation renewable energy source. We are accelerating business activities that contribute to protecting the environment.

Creating Comfortable, Safe Living Spaces that Save Energy

(Oiles ECO Corporation)

Oiles ECO develops and provides products that control natural energy, such as airflow, which is difficult for air conditioning systems to do independently. It is therefore helping to reduce environmental impact, as its products save energy and create comfortable living spaces in all sorts of structures, from high-rise buildings to residential homes.

ECOSHADE, an external electric blind for buildings, blocks sunlight on the outside of a window like a bamboo blind. This helps to keep the temperature inside from rising, thus saving energy. The ECORATOR, otherwise known as the Eco-Supli, is a natural ventilator for buildings without openable windows. It brings natural air inside, improving cooling efficiency to make living spaces more comfortable.

An external blind for homes, BRIIL combines the functions of a shutter and blind, controls natural light, and cuts off about 80% of solar radiation heat from entering the window (heat insulation). It also reduces the air-conditioning load by curbing the rise in surface temperature of window glass by about 10°C compared to interior blinds and is thus a means of energy conservation in homes and low-rise buildings. In light of this, we are promoting BRIIL and its functions through online and TV advertising as part of a strategy for general consumers.